Steph Millard of the exhibitions team at The Science Museum looks back over 100 years of stainless steel, first cast in August 1913 by Harry Brearley

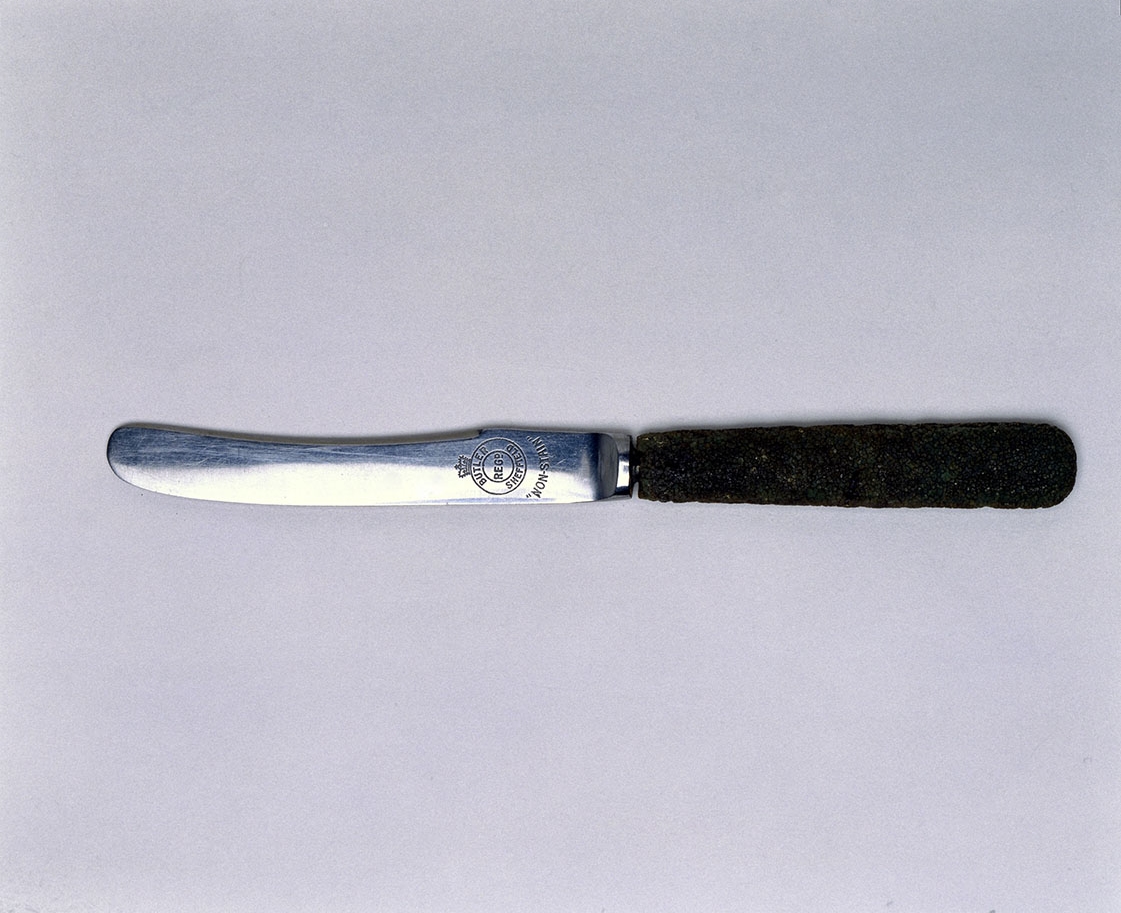

An early stainless steel knife made by Butler of Sheffield, c. 1915. © Science Museum/SSPL

Today’s journey into work sets me thinking. Stuck behind a queue of cars with their stainless steel exhaust systems I repeatedly glance at my wristwatch – with its stainless steel back – to check I won’t be late. To my right, the Canary Wharf tower – with its 370,000 square feet of stainless steel cladding – glints majestically in the early morning sunshine.

Stainless steel impacts on our lives in so many different ways. But what exactly is it and who invented it? One hundred and one years ago, in August 1913, an Englishman named Harry Brearley reported that he had cast an ingot of low-carbon steel that could resist attack from a variety of acids including lemon juice and vinegar. He called it ‘rustless steel’.

At the time, Brearley had been helping an arms manufacturer overcome the problem of gun barrel erosion caused by the release of gases when the weapon is fired. His genius lay in the fact that he could foresee the commercial application of his new material within the cutlery industry. After initial scepticism, manufacturers in his home town of Sheffield were also able to recognise the potential.

The essential ingredient of any stainless steel is chromium, which combines with oxygen in the air to form a strong, invisible film – a protective coating on the surface of the metal that continually self-repairs whenever scratched or grazed. But Brearley was by no means the first person to investigate the addition of chromium to steel. In the century before his discovery metallurgists from across Europe and North America were also experimenting with iron-chromium alloys.

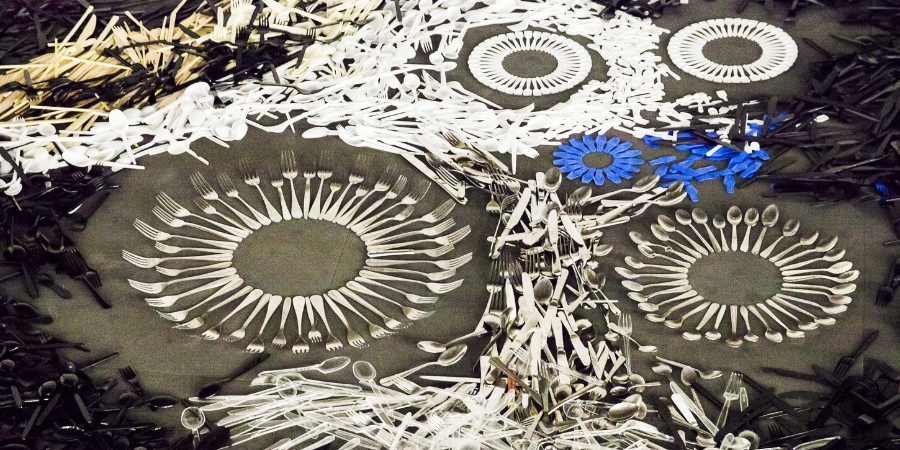

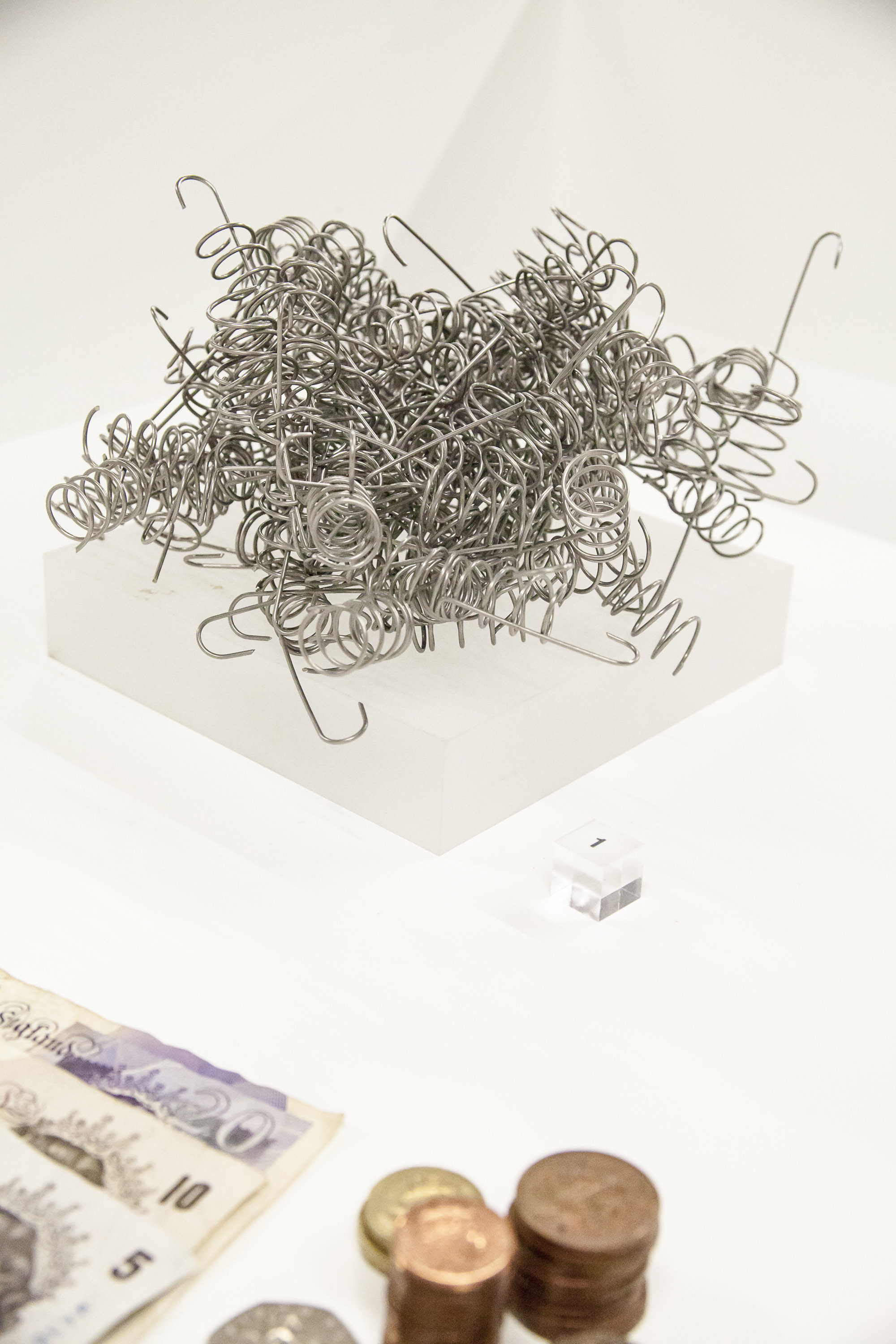

Since then stainless steel – in all its various forms – has gone on to find a home in the widest range of applications, as a walk around the Science Museum’s galleries will testify. Within our Challenge of Materials gallery visitors can admire a wedding dress made of stainless steel wire – the brainchild of British designer Jeff Banks – while in the Exploring Space gallery our J2 rocket engine can remind us that between 1967 and 1973 NASA used stainless steel in all 13 of its Saturn V rockets.

Smaller, but equally intriguing, is the stainless steel dropper on display in The Science and Art of Medicine gallery, which instils oils through the nose as part of an Ayurvedic detox therapy to cure head ailments, such as migraine and sinusitis.

As we celebrate Brearley’s role in the history of metallurgy why not come along to the Science Museum and see how many different examples of stainless steel you can discover?

This article was taken from The Science Museum's blog.