Frames & forks

We're proud of the fact that Series 01 of Milk Bikes is almost entirely made on British soil. Firstly, the frame and forks are made by an up-and-coming frame builder called Jon Davis, who founded Fresh Fabrications last year, based in Croydon. Jon has an impressive bike building background (including working with the likes of Brompton), an eye for detail and is meticulous in his work. The frames he produces are always beautifully finished, which is why we were keen to work with him on this project – our first homemade frame.

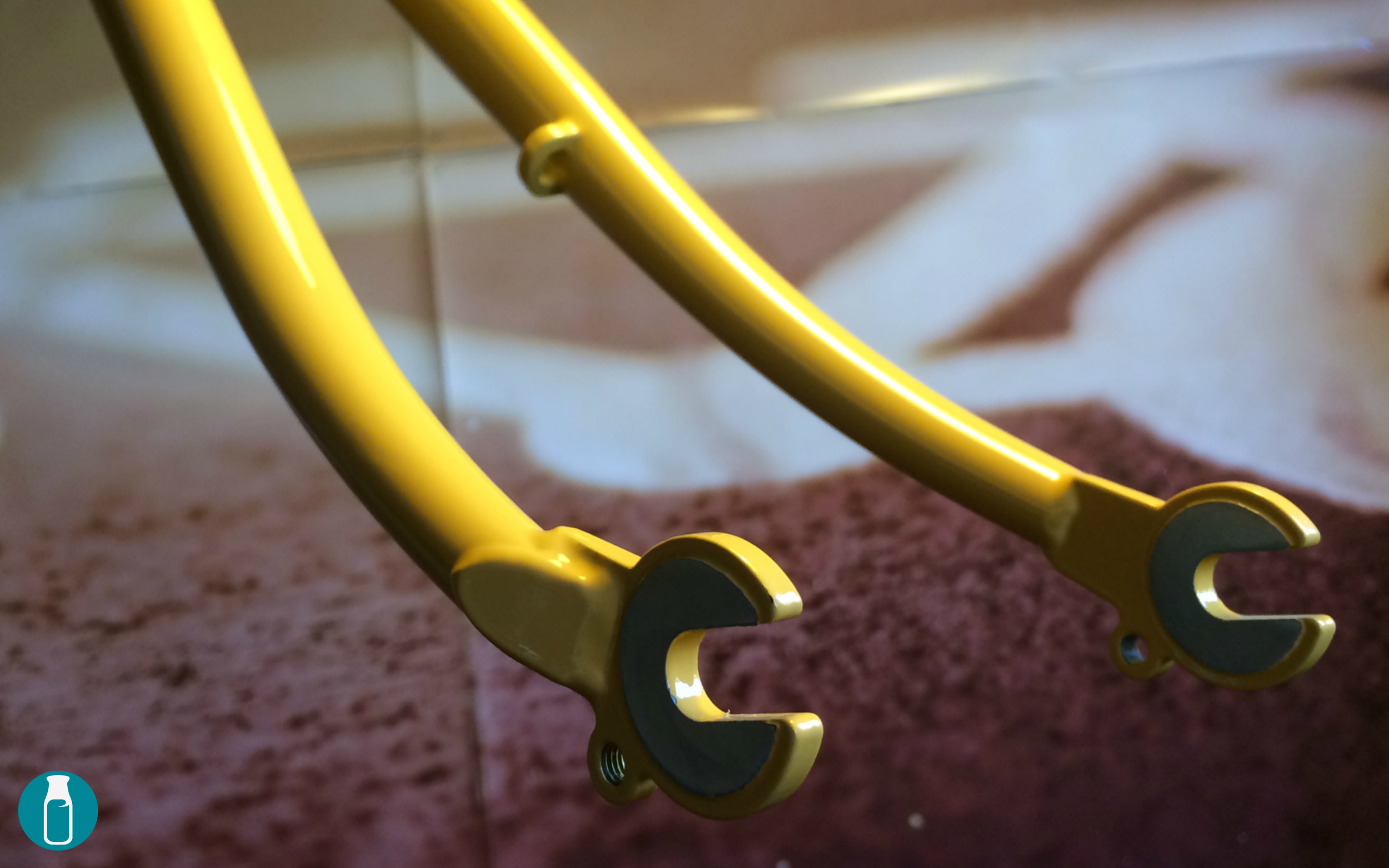

Tube bending

One of the key visual aspects of the bikes is the curves, which are nicely highlighted by the paintwork. The bending is very hard to get right. If anyone has ever bent a tube, they'd know how easy it is to make ripples or crush the tube. There's also a varying amount of spring-back, depending on the size and type of tube. It took a couple of attempts before we were happy.

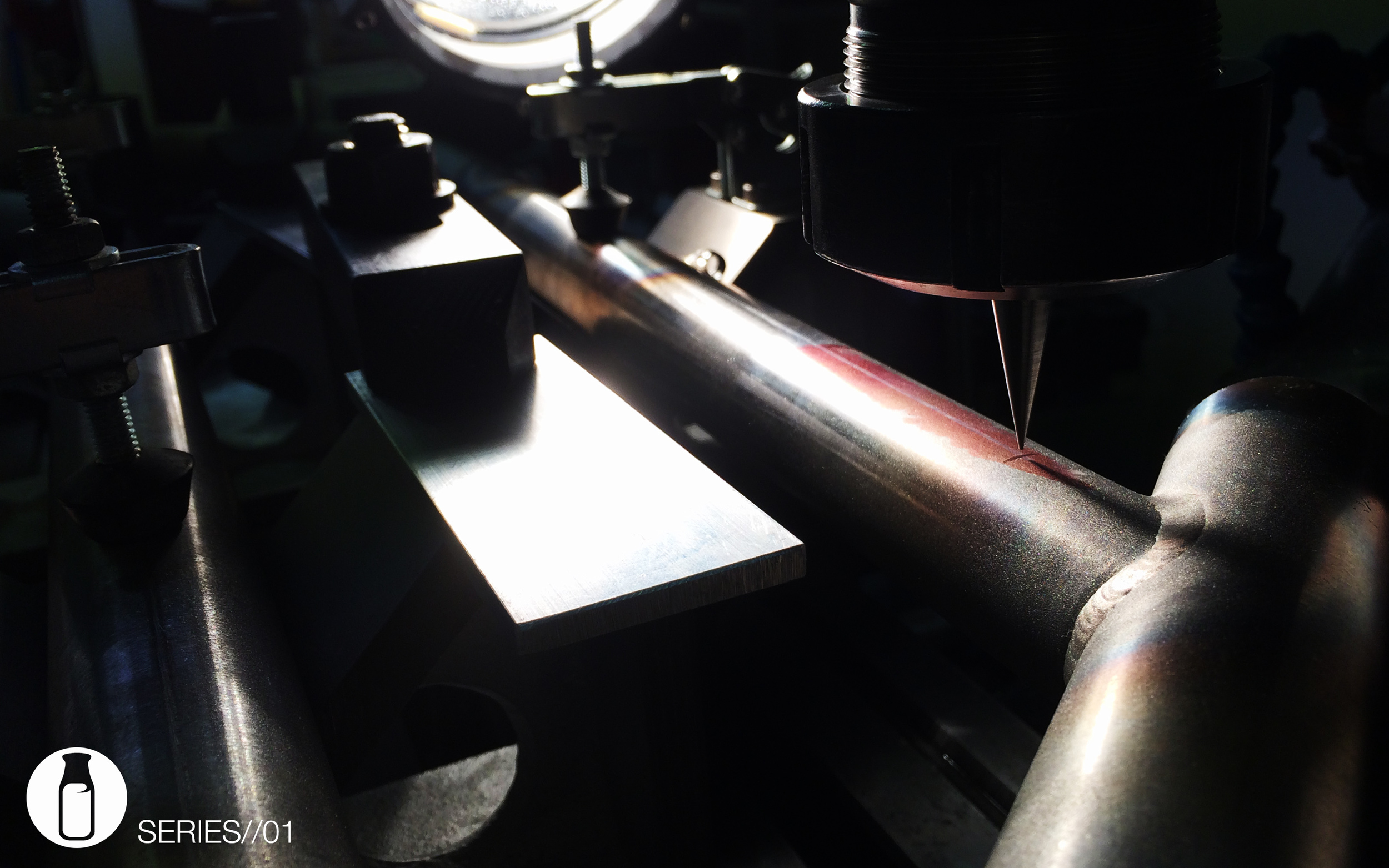

Silver soldering

The frame is fabricated using a combination of TIG welding and silver soldering. You've got to be on the top of your game for this, particularly on the TIG side of things, because the weld bead remains visible on the finished frame. Any dodgy bits will be there for the world to see.

Tube mitring

We use a CNC milling machine to do most of the drilling and tube mitring so we know the accuracy will be fantastic. We also CNC custom dropouts and plates for the fork and chainstay crowns.

Spray the frame

The frame is then sprayed by the chaps down at Argos Cycles, then Simon from Woodguards adds the wooden parts. Once the wheels are added - that's it. We have a Series 01 Milk Bike.